🔬💎 Carbide-Forming Elements in Wootz Steel: ⚙️ Strengths, 🧪 Effects, and 🔥 Concentration Thresholds

Quote from Jacob Christian on August 7, 2025, 3:07 pmHere is a comprehensive list of carbide-forming elements found (or potentially included) in Wootz steel, along with their:

Relative carbide-forming strength

Effects on microstructure and pattern

Influence on mechanical properties

Notable concentrations for visible or functional impact

⚙️ LEGEND

Carbide-forming strength: Compared to iron; 1 = weak (cementite), 10 = very strong.

Typical concentration thresholds:

Trace (< 0.05%)

Minor (0.05–0.15%)

Moderate (0.15–0.5%)

High (> 0.5%)

🔩 1. Vanadium (V)

Carbide strength: 9/10

Carbide formed: VC (vanadium carbide)

Effects:

Strong grain refiner.

Promotes spheroidization at low levels.

Stabilizes small, dispersed carbides.

Inhibits cementite coarsening.

Notable effects at: 0.015–0.05% (grain refinement); >0.1% (cementite inhibition)

Visual/Pattern impact: Can suppress bold patterns if too high due to carbide pinning.

🔩 2. Chromium (Cr)

Carbide strength: 7/10

Carbide formed: Cr₇C₃, Cr₂₃C₆

Effects:

Increases hardenability.

Promotes alloy carbides that are stable at high temps.

Slows cementite dissolution during austenitization.

Notable effects at: >0.05% (cementite stabilization); >0.3% (corrosion resistance and alloy carbide formation)

Visual impact: Helps maintain proeutectoid cementite during pattern formation if balanced.

🔩 3. Molybdenum (Mo)

Carbide strength: 8/10

Carbide formed: Mo₂C

Effects:

Deep hardening.

Prevents softening during tempering.

Improves toughness, red hardness.

Notable effects at: >0.1%

Visual/Pattern impact: Can suppress or compete with cementite, potentially leading to spotty or disrupted patterns if excessive.

🔩 4. Tungsten (W)

Carbide strength: 9.5/10

Carbide formed: WC

Effects:

High-temperature strength and red hardness.

Strong cementite coarsening inhibitor.

Notable effects at: >0.2% (tool steel levels start ~1%)

Visual impact: Fine carbide pinning; excess leads to subtle or suppressed patterns.

🔩 5. Titanium (Ti)

Carbide strength: 10/10

Carbide formed: TiC (extremely stable)

Effects:

Strong grain refiner (due to TiN or TiC nucleation).

Reacts early during solidification—strong deoxidizer.

Notable effects at: ~0.01–0.03%

Visual/Pattern impact: Can inhibit bold banding; more useful for grain control in high-alloy steels.

🔩 6. Niobium (Nb)

Carbide strength: 9.5/10

Carbide formed: NbC

Effects:

Strong grain boundary pinning.

Promotes ultra-fine grain size.

Notable effects at: >0.02%

Visual/Pattern impact: Reduces coarseness; not typical in traditional Wootz.

🔩 7. Tantalum (Ta) (rare in Wootz)

Carbide strength: 10/10

Carbide formed: TaC

Effects:

High-melting carbide; extremely stable.

Notable effects at: >0.05%

Visual/Pattern impact: Inhibits pattern formation at high levels due to carbide pinning.

🔩 8. Manganese (Mn)

Carbide strength: ~4/10 (moderate)

Carbide formed: Mn₃C (less stable)

Effects:

Increases hardenability.

Affects eutectoid composition and transformation kinetics.

Suppresses carbide coarsening slightly at higher levels.

Notable effects at: >0.3% (not desired in traditional Wootz)

Visual/Pattern impact: Can muddy patterns and reduce cementite banding if too high.

🔩 9. Silicon (Si) (indirect effect)

Carbide strength: 2/10 (weak)

Effects:

Promotes ferrite formation.

Slightly strengthens matrix.

Slightly slows cementite spheroidization.

Notable effects at: >0.3%

Visual/Pattern impact: Can cause ghost banding or enhance contrast if balanced.

🔩 10. Phosphorus (P) (not a carbide-former but affects carbide behavior)

Effects:

Segregates to grain boundaries.

Enhances wetting and band formation of proeutectoid cementite.

Notable effects at: 0.03–0.06% (ideal for Wootz patterning)

Visual/Pattern impact: Strong enhancer of cementite contrast and banding clarity.

🔩 11. Sulfur (S) (included for context)

Not a carbide former, but can promote MnS inclusions that may act as nucleation sites.

High S is undesirable.

🔩 12. Copper (Cu) (not a carbide-former)

Promotes grain boundary cohesion and may influence corrosion resistance.

May affect etching contrast or pattern clarity at >0.05%.

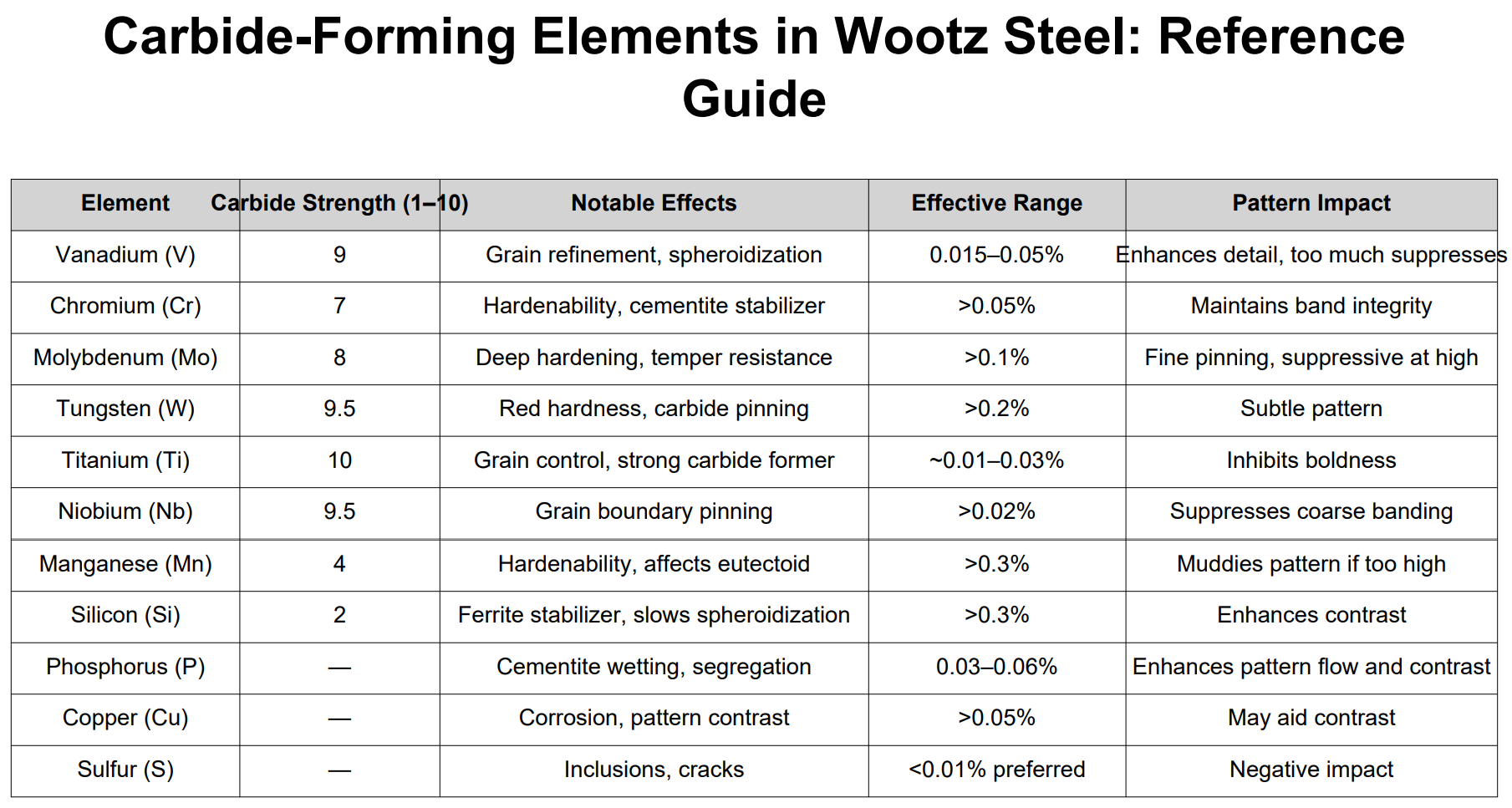

🧬 Summary Table

Element Carbide Strength (1–10) Notable Effects Effective Range in Wootz Pattern Impact V 9 Grain refinement, spheroidization 0.015–0.05% Enhances detail, too much suppresses Cr 7 Hardenability, cementite stabilizer >0.05% Maintains band integrity Mo 8 Deep hardening, temper resistance >0.1% Fine pinning, suppressive at high W 9.5 Red hardness, carbide pinning >0.2% Subtle pattern Ti 10 Grain control, strong carbide former ~0.01–0.03% Inhibits boldness Nb 9.5 Grain boundary pinning >0.02% Suppresses coarse banding Mn 4 Hardenability, affects eutectoid >0.3% Muddies pattern if too high Si 2 Ferrite stabilizer, slows spheroidization >0.3% Enhances contrast P — Cementite wetting, segregation 0.03–0.06% Enhances pattern flow and contrast Cu — Corrosion, pattern contrast >0.05% May aid contrast S — Inclusions, cracks <0.01% preferred Negative impact

🔧 Notes for Wootz-Smithing:

Ideal alloys: Fe + 1.4–1.6%C, 0.03–0.05% P, ~0.02% V, ~0.02–0.05% Cr

Avoid too much Cr, Mo, or V unless carefully controlled—they can inhibit cementite migration and bold pattern formation

Traditional Wootz owes much of its banding to cementite segregation, slow cooling, and mild carbide pinning, not extreme carbide stability

Here is a comprehensive list of carbide-forming elements found (or potentially included) in Wootz steel, along with their:

-

Relative carbide-forming strength

-

Effects on microstructure and pattern

-

Influence on mechanical properties

-

Notable concentrations for visible or functional impact

⚙️ LEGEND

-

Carbide-forming strength: Compared to iron; 1 = weak (cementite), 10 = very strong.

-

Typical concentration thresholds:

-

Trace (< 0.05%)

-

Minor (0.05–0.15%)

-

Moderate (0.15–0.5%)

-

High (> 0.5%)

-

🔩 1. Vanadium (V)

-

Carbide strength: 9/10

-

Carbide formed: VC (vanadium carbide)

-

Effects:

-

Strong grain refiner.

-

Promotes spheroidization at low levels.

-

Stabilizes small, dispersed carbides.

-

Inhibits cementite coarsening.

-

-

Notable effects at: 0.015–0.05% (grain refinement); >0.1% (cementite inhibition)

-

Visual/Pattern impact: Can suppress bold patterns if too high due to carbide pinning.

🔩 2. Chromium (Cr)

-

Carbide strength: 7/10

-

Carbide formed: Cr₇C₃, Cr₂₃C₆

-

Effects:

-

Increases hardenability.

-

Promotes alloy carbides that are stable at high temps.

-

Slows cementite dissolution during austenitization.

-

-

Notable effects at: >0.05% (cementite stabilization); >0.3% (corrosion resistance and alloy carbide formation)

-

Visual impact: Helps maintain proeutectoid cementite during pattern formation if balanced.

🔩 3. Molybdenum (Mo)

-

Carbide strength: 8/10

-

Carbide formed: Mo₂C

-

Effects:

-

Deep hardening.

-

Prevents softening during tempering.

-

Improves toughness, red hardness.

-

-

Notable effects at: >0.1%

-

Visual/Pattern impact: Can suppress or compete with cementite, potentially leading to spotty or disrupted patterns if excessive.

🔩 4. Tungsten (W)

-

Carbide strength: 9.5/10

-

Carbide formed: WC

-

Effects:

-

High-temperature strength and red hardness.

-

Strong cementite coarsening inhibitor.

-

-

Notable effects at: >0.2% (tool steel levels start ~1%)

-

Visual impact: Fine carbide pinning; excess leads to subtle or suppressed patterns.

🔩 5. Titanium (Ti)

-

Carbide strength: 10/10

-

Carbide formed: TiC (extremely stable)

-

Effects:

-

Strong grain refiner (due to TiN or TiC nucleation).

-

Reacts early during solidification—strong deoxidizer.

-

-

Notable effects at: ~0.01–0.03%

-

Visual/Pattern impact: Can inhibit bold banding; more useful for grain control in high-alloy steels.

🔩 6. Niobium (Nb)

-

Carbide strength: 9.5/10

-

Carbide formed: NbC

-

Effects:

-

Strong grain boundary pinning.

-

Promotes ultra-fine grain size.

-

-

Notable effects at: >0.02%

-

Visual/Pattern impact: Reduces coarseness; not typical in traditional Wootz.

🔩 7. Tantalum (Ta) (rare in Wootz)

-

Carbide strength: 10/10

-

Carbide formed: TaC

-

Effects:

-

High-melting carbide; extremely stable.

-

-

Notable effects at: >0.05%

-

Visual/Pattern impact: Inhibits pattern formation at high levels due to carbide pinning.

🔩 8. Manganese (Mn)

-

Carbide strength: ~4/10 (moderate)

-

Carbide formed: Mn₃C (less stable)

-

Effects:

-

Increases hardenability.

-

Affects eutectoid composition and transformation kinetics.

-

Suppresses carbide coarsening slightly at higher levels.

-

-

Notable effects at: >0.3% (not desired in traditional Wootz)

-

Visual/Pattern impact: Can muddy patterns and reduce cementite banding if too high.

🔩 9. Silicon (Si) (indirect effect)

-

Carbide strength: 2/10 (weak)

-

Effects:

-

Promotes ferrite formation.

-

Slightly strengthens matrix.

-

Slightly slows cementite spheroidization.

-

-

Notable effects at: >0.3%

-

Visual/Pattern impact: Can cause ghost banding or enhance contrast if balanced.

🔩 10. Phosphorus (P) (not a carbide-former but affects carbide behavior)

-

Effects:

-

Segregates to grain boundaries.

-

Enhances wetting and band formation of proeutectoid cementite.

-

-

Notable effects at: 0.03–0.06% (ideal for Wootz patterning)

-

Visual/Pattern impact: Strong enhancer of cementite contrast and banding clarity.

🔩 11. Sulfur (S) (included for context)

-

Not a carbide former, but can promote MnS inclusions that may act as nucleation sites.

-

High S is undesirable.

🔩 12. Copper (Cu) (not a carbide-former)

-

Promotes grain boundary cohesion and may influence corrosion resistance.

-

May affect etching contrast or pattern clarity at >0.05%.

🧬 Summary Table

| Element | Carbide Strength (1–10) | Notable Effects | Effective Range in Wootz | Pattern Impact |

|---|---|---|---|---|

| V | 9 | Grain refinement, spheroidization | 0.015–0.05% | Enhances detail, too much suppresses |

| Cr | 7 | Hardenability, cementite stabilizer | >0.05% | Maintains band integrity |

| Mo | 8 | Deep hardening, temper resistance | >0.1% | Fine pinning, suppressive at high |

| W | 9.5 | Red hardness, carbide pinning | >0.2% | Subtle pattern |

| Ti | 10 | Grain control, strong carbide former | ~0.01–0.03% | Inhibits boldness |

| Nb | 9.5 | Grain boundary pinning | >0.02% | Suppresses coarse banding |

| Mn | 4 | Hardenability, affects eutectoid | >0.3% | Muddies pattern if too high |

| Si | 2 | Ferrite stabilizer, slows spheroidization | >0.3% | Enhances contrast |

| P | — | Cementite wetting, segregation | 0.03–0.06% | Enhances pattern flow and contrast |

| Cu | — | Corrosion, pattern contrast | >0.05% | May aid contrast |

| S | — | Inclusions, cracks | <0.01% preferred | Negative impact |

🔧 Notes for Wootz-Smithing:

-

Ideal alloys: Fe + 1.4–1.6%C, 0.03–0.05% P, ~0.02% V, ~0.02–0.05% Cr

-

Avoid too much Cr, Mo, or V unless carefully controlled—they can inhibit cementite migration and bold pattern formation

-

Traditional Wootz owes much of its banding to cementite segregation, slow cooling, and mild carbide pinning, not extreme carbide stability

Uploaded files: