Beginner "Analog wootz" recipe?

Quote from John Logan on October 8, 2025, 7:49 amHey wootz smiths total wootz beginner here. I started playing with melt techniques on my induction forge a few months back and got the bug. Been sourcing ingredients; electrolytic iron, carbon sources, carbiding elements from Jacob Christian, etc, etc. Now with the weather cooling off I am eager to get back into it! But I don't know where to begin....

I have played around with the wootz calculator and have gotten it to spit out interesting data points but without knowing what I am aiming for it leaves too many variables for it to function properly, let alone give me anything close to a "recipe". Curious if something could be shared for starting out with common ingredients? Something forgeable with nice pattern potential maybe sizeable to the crucible?

I am in no way asking for a free handout of info I know people have worked hard to get, just a starting place to get everything rolling. In the dirt-to-iron Smelting circle we have something we call "Analog ore" that we use for testing purposes using pottery oxides as a constant. It's a recipe that allows the experimenter to focus on all the other variables such as furnace and air supply before delving into the less forgiving natural ores. Could there be an "Analog wootz" recipe and/or calculator for those of us starting out so we can get ALL the other parts of the puzzle ironed out before we dive deep into calculating our own alloys?

I look forward to the replies and getting back into the swing of making steel!

Hey wootz smiths total wootz beginner here. I started playing with melt techniques on my induction forge a few months back and got the bug. Been sourcing ingredients; electrolytic iron, carbon sources, carbiding elements from Jacob Christian, etc, etc. Now with the weather cooling off I am eager to get back into it! But I don't know where to begin....

I have played around with the wootz calculator and have gotten it to spit out interesting data points but without knowing what I am aiming for it leaves too many variables for it to function properly, let alone give me anything close to a "recipe". Curious if something could be shared for starting out with common ingredients? Something forgeable with nice pattern potential maybe sizeable to the crucible?

I am in no way asking for a free handout of info I know people have worked hard to get, just a starting place to get everything rolling. In the dirt-to-iron Smelting circle we have something we call "Analog ore" that we use for testing purposes using pottery oxides as a constant. It's a recipe that allows the experimenter to focus on all the other variables such as furnace and air supply before delving into the less forgiving natural ores. Could there be an "Analog wootz" recipe and/or calculator for those of us starting out so we can get ALL the other parts of the puzzle ironed out before we dive deep into calculating our own alloys?

I look forward to the replies and getting back into the swing of making steel!

Quote from Jerry Martin on October 14, 2025, 2:24 pmI'm not much help. I mostly cast Bronze and Aluminum. I plan to try some Wootz soon. My basic plan is to dump a bunch of stuff together, take copious notes and weights and see what turns out. Then try to adjust the recipe. I used to have access to a Spectrometer, but I retired. Keep us posted on how yours turns out. Good Luck.

I'm not much help. I mostly cast Bronze and Aluminum. I plan to try some Wootz soon. My basic plan is to dump a bunch of stuff together, take copious notes and weights and see what turns out. Then try to adjust the recipe. I used to have access to a Spectrometer, but I retired. Keep us posted on how yours turns out. Good Luck.

Quote from Jacob Christian on October 29, 2025, 12:47 pmHey John,

Here are some old wootz blade chemistries that came from Verhoeven that I converted into weight percent's.

Table IV. Chemical Analysis of Seven Wootz Damascus Blades* Element 7 9 10 Old B Figiel Voigt Kard C 1.71 1.41 1.79 1.51 1.64 1 1.49 Mn 0.015 0.01 0.03 0.01 0.02 0.05 0.01 V 0.0145 0.005 0.027 0.004 0.004 0.001 0.006 Cr 0.01 0.01 0.01 0.01 0.01 0.01 0.01 P 0.101 0.098 0.133 0.095 0.162 0.026 0.144 S 0.0095 0.006 0.016 0.0053 0.0085 0.0115 0.009 Mo 0.01 0.01 0.01 0.01 0.01 0.01 0.01 Nb 0.01 0.01 0.01 0.01 0.01 0.01 0.01 Ti 0.0009 0.0011 0.0006 0.0013 0.0016 0.0007 0.0019 Zr 0.001 0.001 0.001 0.001 0.001 0.001 0.001 Si 0.035 0.05 0.05 0.047 0.046 0.0975 0.05 Cu 0.175 0.09 0.183 0.033 0.078 0.03 0.09 Ni 0.06 0.04 0.07 0.01 0.018 0.01 0.02 Sn 0.001 0.001 0.001 0.001 0.001 0.0015 0.001 Al 0.001 0.001 0.001 0.0012 0.0008 0.0025 0.003 B 0.0001 0.0001 0.0001 0.0001 0.0002 0.0001 0.0001 Ca 0.0019 0.0017 0.0015 0.0011 0.0002 0.0013 0.0001 Pb 0.001 0.001 0.001 0.001 0.001 0.001 0.004

Then with all of that information people normally go with a lower P content.

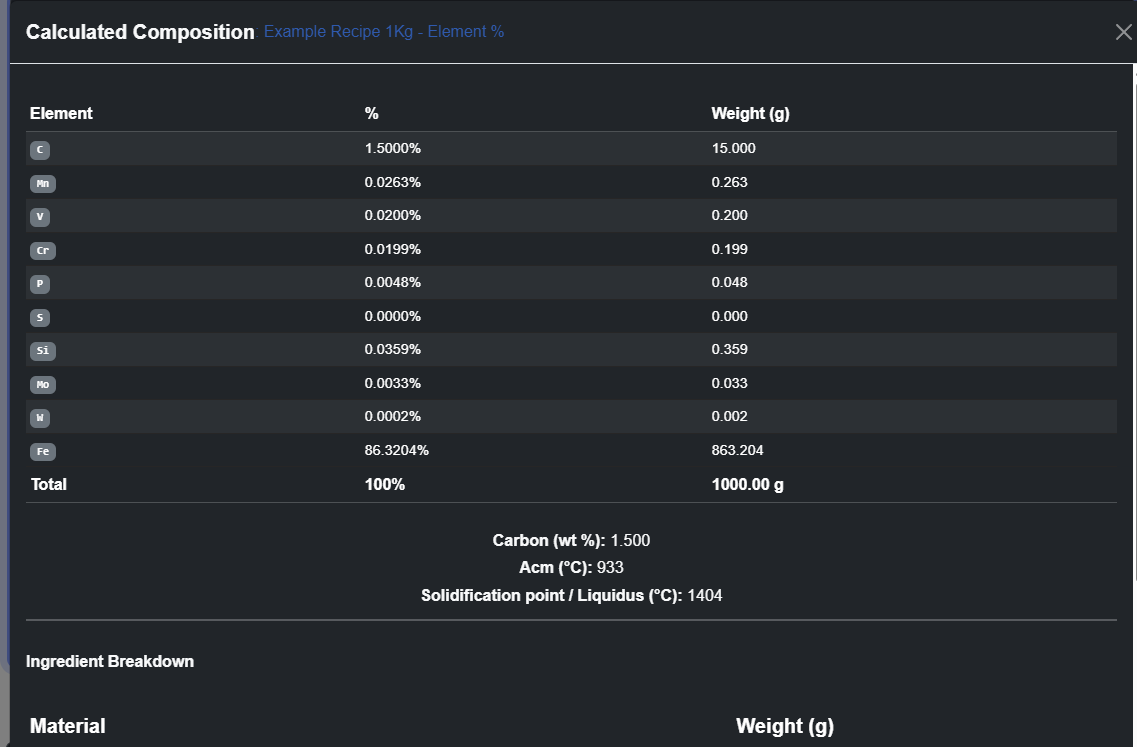

Some typical started chemistries look something like this.

Along with all of this information, there are plenty of my posts on here that share chemistries that I was working on at the time.

Your best bet with all of the ingredients will be having them in powder form. Powder more easily melts than larger pieces of steel. If you do use larger pieces of steel, then you have hold at the melt temp for a longer time.

Personally, I use powder 1095 in almost all of my melts.

Hey John,

Here are some old wootz blade chemistries that came from Verhoeven that I converted into weight percent's.

| Table IV. Chemical Analysis of Seven Wootz Damascus Blades* | |||||||

| Element | 7 | 9 | 10 | Old B | Figiel | Voigt | Kard |

| C | 1.71 | 1.41 | 1.79 | 1.51 | 1.64 | 1 | 1.49 |

| Mn | 0.015 | 0.01 | 0.03 | 0.01 | 0.02 | 0.05 | 0.01 |

| V | 0.0145 | 0.005 | 0.027 | 0.004 | 0.004 | 0.001 | 0.006 |

| Cr | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| P | 0.101 | 0.098 | 0.133 | 0.095 | 0.162 | 0.026 | 0.144 |

| S | 0.0095 | 0.006 | 0.016 | 0.0053 | 0.0085 | 0.0115 | 0.009 |

| Mo | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Nb | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Ti | 0.0009 | 0.0011 | 0.0006 | 0.0013 | 0.0016 | 0.0007 | 0.0019 |

| Zr | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Si | 0.035 | 0.05 | 0.05 | 0.047 | 0.046 | 0.0975 | 0.05 |

| Cu | 0.175 | 0.09 | 0.183 | 0.033 | 0.078 | 0.03 | 0.09 |

| Ni | 0.06 | 0.04 | 0.07 | 0.01 | 0.018 | 0.01 | 0.02 |

| Sn | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.0015 | 0.001 |

| Al | 0.001 | 0.001 | 0.001 | 0.0012 | 0.0008 | 0.0025 | 0.003 |

| B | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0002 | 0.0001 | 0.0001 |

| Ca | 0.0019 | 0.0017 | 0.0015 | 0.0011 | 0.0002 | 0.0013 | 0.0001 |

| Pb | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.004 |

Then with all of that information people normally go with a lower P content.

Some typical started chemistries look something like this.

Along with all of this information, there are plenty of my posts on here that share chemistries that I was working on at the time.

Your best bet with all of the ingredients will be having them in powder form. Powder more easily melts than larger pieces of steel. If you do use larger pieces of steel, then you have hold at the melt temp for a longer time.

Personally, I use powder 1095 in almost all of my melts.

Uploaded files:Quote from Jacob Christian on October 29, 2025, 12:53 pmThis post also have some great information on the effects of carbide forming elements.

Traditional wootz steel has total CFEs in the range of no more that .1% total. In my book, anything that has carbide banding, melted in a crucible and forged out will count as wootz. Another useful thing to look at is currently chemistries on steels today and look at the proportions. The proportions are that way for a reason. For example, adding Mn to cancel out S.

This post also have some great information on the effects of carbide forming elements.

Traditional wootz steel has total CFEs in the range of no more that .1% total. In my book, anything that has carbide banding, melted in a crucible and forged out will count as wootz. Another useful thing to look at is currently chemistries on steels today and look at the proportions. The proportions are that way for a reason. For example, adding Mn to cancel out S.