Quote from Jacob Christian on July 3, 2022, 2:04 pmHello Everyone,

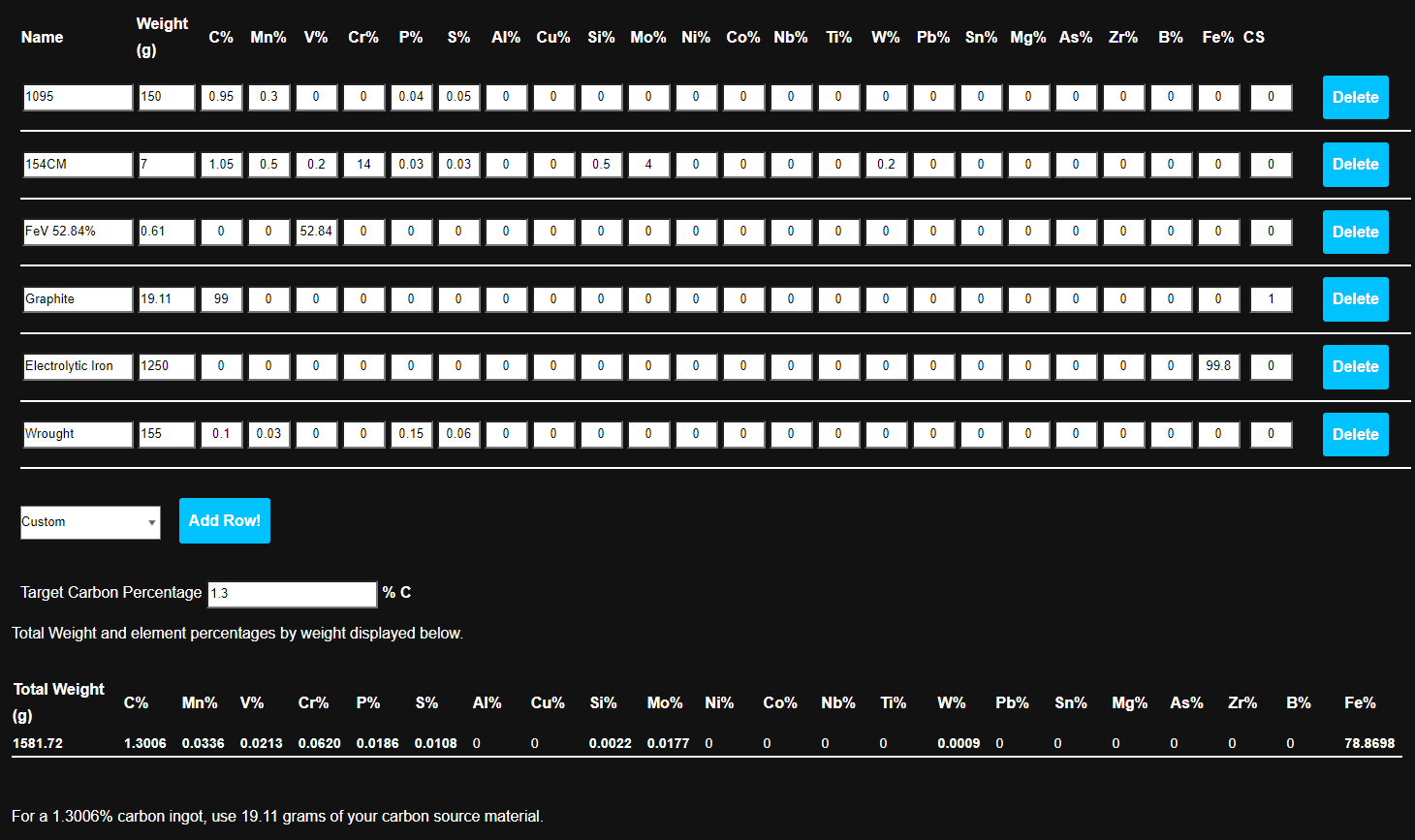

We are switching it up a little today with a 1.3% wootz ingot. The recipe below is exactly what was put into the crucible. I think that it was an A4 crucible that was used.

Ingot with fairly course dendritic structure. Should end up with a splendid pattern!

Hello Everyone,

We are switching it up a little today with a 1.3% wootz ingot. The recipe below is exactly what was put into the crucible. I think that it was an A4 crucible that was used.

Ingot with fairly course dendritic structure. Should end up with a splendid pattern!

Quote from Jacob Christian on August 16, 2022, 1:43 pmAfter further working of the ingot, I have noticed that the steel etches rather dark. You can see the pattern but definitely have to look closely. I am thinking that this is the product of less and or smaller carbides being created. If this is the case the hardened steel is etching so dark that it is washing out the cementite. I will probably be sticking with 1.5% ingots in the future.

Here is a chefs knife made from the ingot.

I have 2 other knives in the making and I will post them when they are completed. I will probably skip the diluted nitric acid and try for a weaker acid such as vinegar.

After further working of the ingot, I have noticed that the steel etches rather dark. You can see the pattern but definitely have to look closely. I am thinking that this is the product of less and or smaller carbides being created. If this is the case the hardened steel is etching so dark that it is washing out the cementite. I will probably be sticking with 1.5% ingots in the future.

Here is a chefs knife made from the ingot.

I have 2 other knives in the making and I will post them when they are completed. I will probably skip the diluted nitric acid and try for a weaker acid such as vinegar.

Uploaded files:Quote from Jacob Christian on August 16, 2022, 1:49 pmAnother thing about the 1.3% wootz is that I have had more difficulty quenching thicker cross sections. Normally I have been using 20 min soak at 780 C and then into parks 50 but considering the extremely low Mn content, it seems more suitable for water quenching. I will be hammering out some test blades soon!

Another thing about the 1.3% wootz is that I have had more difficulty quenching thicker cross sections. Normally I have been using 20 min soak at 780 C and then into parks 50 but considering the extremely low Mn content, it seems more suitable for water quenching. I will be hammering out some test blades soon!

Quote from Jacob Christian on September 26, 2022, 9:26 amSame issues with etching. Pattern is very difficult to see.

Unless specifically needed for a water quench I will probably also be uping the Mn content. Blades are not through hardening in parks 50 moving from .03 to around .04 Mn

Same issues with etching. Pattern is very difficult to see.

Unless specifically needed for a water quench I will probably also be uping the Mn content. Blades are not through hardening in parks 50 moving from .03 to around .04 Mn

Uploaded files: