Quote from Jacob Christian on May 28, 2024, 7:27 amHello Everyone,

So this was an experiment to see what would happen if I copied the chemical composition of 26C3 steel and then forge it out in the same manner as I would wootz steel. This was in an attempt to make a superior wootz steel that could have better toughness properties while maintaining its fantastic edge retention properties. Another added benefit is that with the increased Mn content, it would make it extremely easy for anyone to heat treat.

Initial thoughts were that the Mn may choke out some of the cementite in the final etching (i.e. The microstructure, even though spheroidite, may still etch extremely black and somewhat cover the CM particles). I may be able to combat this with using a weaker acid. I was also curious to see if the increased amount of Cr would create the very recognizable High Cr patterns in wootz.

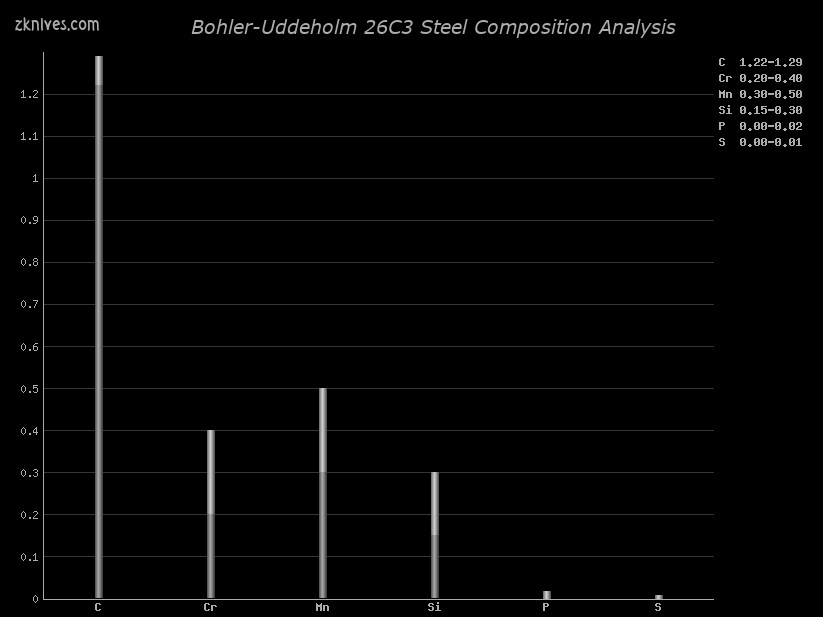

For the chemical composition, I followed what was documented by z-knives above.

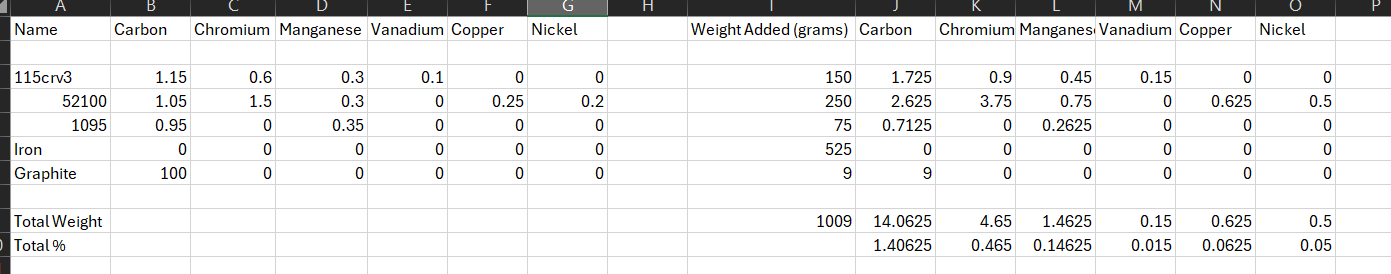

Here is the composition that I calculated.

The ingot after being removed from the crucible.

The ingot was then roasted at 1080 C for 5 hours, followed by immediate forging to close up any micro-porosity.

This was then followed by my normal wootz forging procedure. Forging a few rounds at 1080C and then bulk material movement at 960 followed by final spheroidite forging at 850-727C.

At this state the pattern was looking very intriguing but that can all change for the better or worse by the time you get to HTing a knife.

I finished the forging and cut the bar up into pieces. Some pieces were sent off for testing and others given to other blacksmiths to 'play' with. The 1600g ingot after being forged out was enough to make about 4 - 8inch full tang knives.

Hello Everyone,

So this was an experiment to see what would happen if I copied the chemical composition of 26C3 steel and then forge it out in the same manner as I would wootz steel. This was in an attempt to make a superior wootz steel that could have better toughness properties while maintaining its fantastic edge retention properties. Another added benefit is that with the increased Mn content, it would make it extremely easy for anyone to heat treat.

Initial thoughts were that the Mn may choke out some of the cementite in the final etching (i.e. The microstructure, even though spheroidite, may still etch extremely black and somewhat cover the CM particles). I may be able to combat this with using a weaker acid. I was also curious to see if the increased amount of Cr would create the very recognizable High Cr patterns in wootz.

For the chemical composition, I followed what was documented by z-knives above.

Here is the composition that I calculated.

The ingot after being removed from the crucible.

The ingot was then roasted at 1080 C for 5 hours, followed by immediate forging to close up any micro-porosity.

This was then followed by my normal wootz forging procedure. Forging a few rounds at 1080C and then bulk material movement at 960 followed by final spheroidite forging at 850-727C.

At this state the pattern was looking very intriguing but that can all change for the better or worse by the time you get to HTing a knife.

I finished the forging and cut the bar up into pieces. Some pieces were sent off for testing and others given to other blacksmiths to 'play' with. The 1600g ingot after being forged out was enough to make about 4 - 8inch full tang knives.

Quote from Jacob Christian on May 28, 2024, 7:34 am

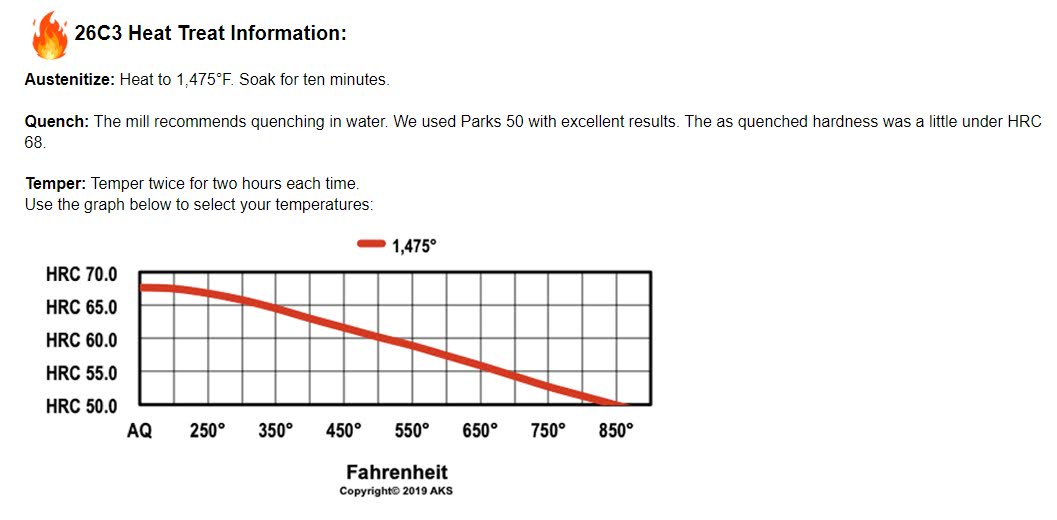

From the pieces that I still had, I was able to make 2 of these 8 inch full tang knives. The bevels were ground and then they were heat treated. I followed AKS recommendation for HT 800C hold for 10 min and into parks 50. The blades came out hard AF! My HRC 65 test file would not even scratch it. 2 x 2 hour temper cycles were done at 232C / 450F which should get me around HRC 62ish. I may need to bump up the temp a bit.... 62 is still kind of hard.

From the pieces that I still had, I was able to make 2 of these 8 inch full tang knives. The bevels were ground and then they were heat treated. I followed AKS recommendation for HT 800C hold for 10 min and into parks 50. The blades came out hard AF! My HRC 65 test file would not even scratch it. 2 x 2 hour temper cycles were done at 232C / 450F which should get me around HRC 62ish. I may need to bump up the temp a bit.... 62 is still kind of hard.

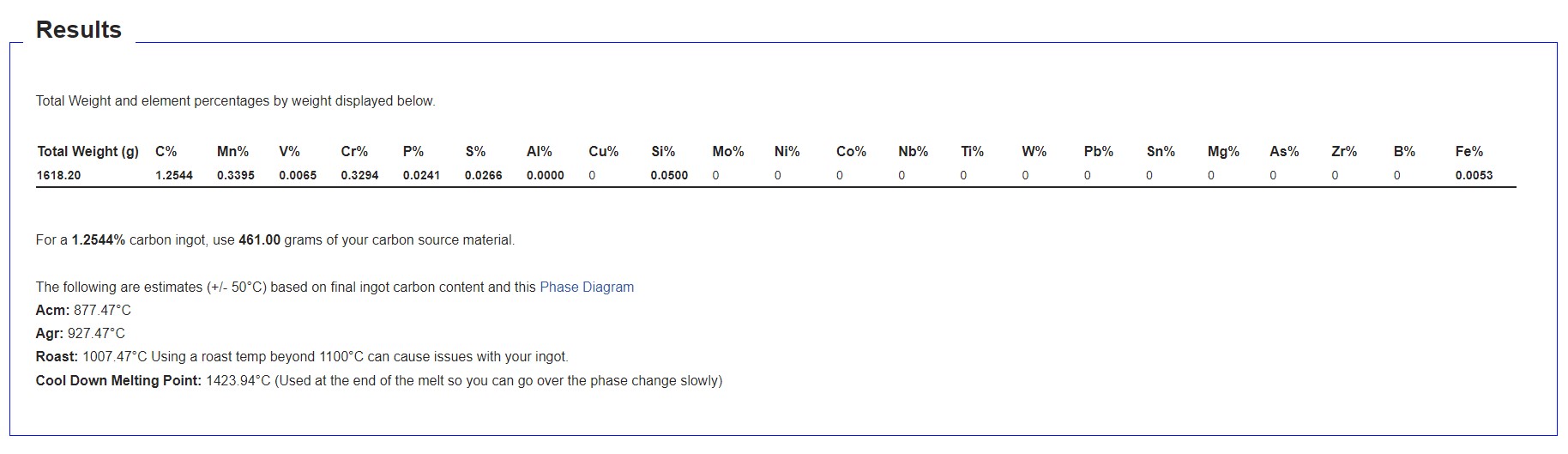

Quote from Raggedyman on July 18, 2024, 6:19 amI've been considering something similar myself, here was my planned load:

I'm finally getting around to building my furnace, you really inspired me to get my act together. Thanks man!

I've been considering something similar myself, here was my planned load:

I'm finally getting around to building my furnace, you really inspired me to get my act together. Thanks man!

Uploaded files:Quote from Jacob Christian on July 22, 2024, 8:05 am@raggedyman

There you go man! Happy to help lol!

That does not look bad at all! The Mn is on the lower side. Be prepared for an auto hamon in using oil.

There you go man! Happy to help lol!

That does not look bad at all! The Mn is on the lower side. Be prepared for an auto hamon in using oil.