Quote from AjfMetalworks on August 21, 2023, 10:13 pmIm looking to produce a basic wootz chemistry without too many alloying elements so i can start sharing and teaching others to bring more people into the craft and SHARE the passion and history with others.

Im looking at already available steels and iron flake as im wanting the ingredients to be somewhat readily available to anyone wanting to join the craft and make there own steel.

So Far im looking at a

1095/1095 powder

o1-w2

graphite/charcoal

Iron flake.

(not so much ferro vandaium as its damn near impossible to get in my part of the world along with other ferro alloys)Im not basing this "basic level" wootz on any historical examples.

As more people come into the craft more and more people have started to "GateKeep" this is not what i envisioned for our community. The community i envisioned "Is a place for sharing knowledge"I would love to hear others thoughts on sharing a basic chemistry with others and running classes and or events.

Im looking to produce a basic wootz chemistry without too many alloying elements so i can start sharing and teaching others to bring more people into the craft and SHARE the passion and history with others.

Im looking at already available steels and iron flake as im wanting the ingredients to be somewhat readily available to anyone wanting to join the craft and make there own steel.

So Far im looking at a

1095/1095 powder

o1-w2

graphite/charcoal

Iron flake.

(not so much ferro vandaium as its damn near impossible to get in my part of the world along with other ferro alloys)

Im not basing this "basic level" wootz on any historical examples.

As more people come into the craft more and more people have started to "GateKeep" this is not what i envisioned for our community. The community i envisioned "Is a place for sharing knowledge"

I would love to hear others thoughts on sharing a basic chemistry with others and running classes and or events.

Quote from Jacob Christian on September 1, 2023, 7:22 am@ajfmetalworks What you listed here is pretty much what I started with in my own melts, minus the electrolytic iron flake because I didnt learn about that until later.

I have used O1 a bit but prefer W2 over it just because it is much less alloyed. I have found that most ferrro alloys that we would use for making wootz are pretty difficult to come across.

Recently I have been using CPM S90V as my vanadium source and CPM 154 for addition of chromium. I am sticking to the CPM steels because of how they are made. The thought is that making steel with particle metallurgy, the distribution of alloying elements should be much more even. So when you calculate a certain piece having a certain amount of vanadium in it, it should hopefully be at least somewhat close to that.

I will also mention that using graphite pellets can be easier to use that graphite powder because it wont blow out of the crucible. If you do use the graphite powder, I would suggest that you mix it with your powdered steel. If you are using different types of powdered steel, mix them all together before pouring it into the crucible. This it will help the graphite be absorbed better. If using the pellets, I would put them closer to the bottom but not at the bottom. They like to float in the glass slag lol....

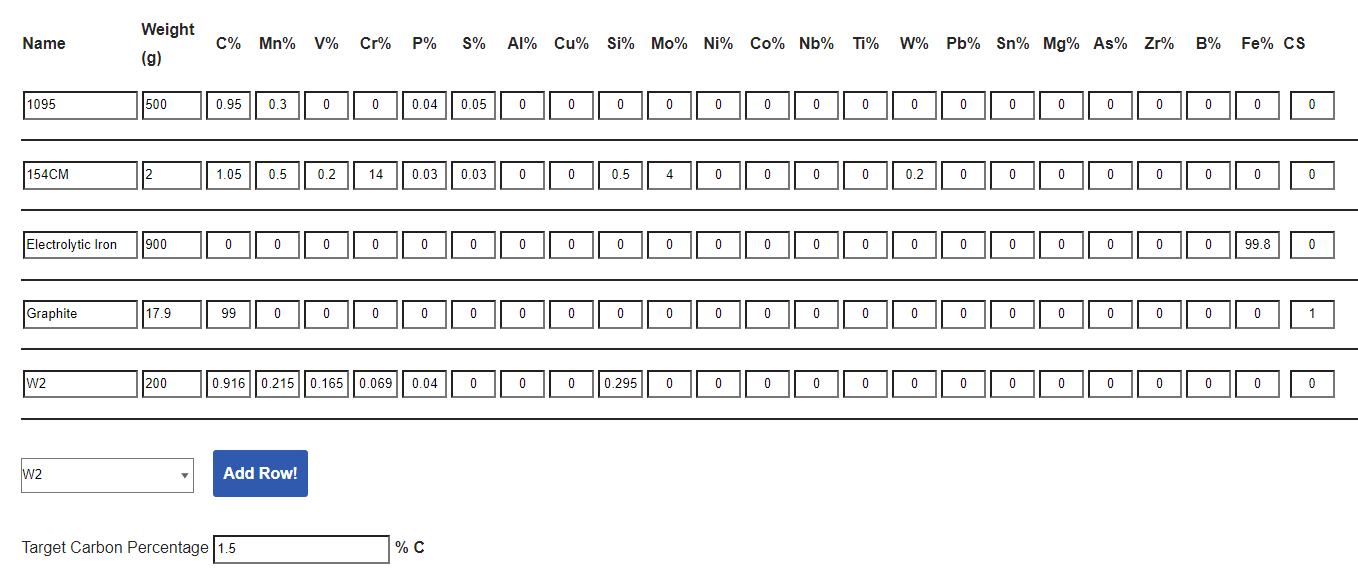

Here is a basic recipe that will give you a decent pattern. It is not historical wootz but not entirely far off either.

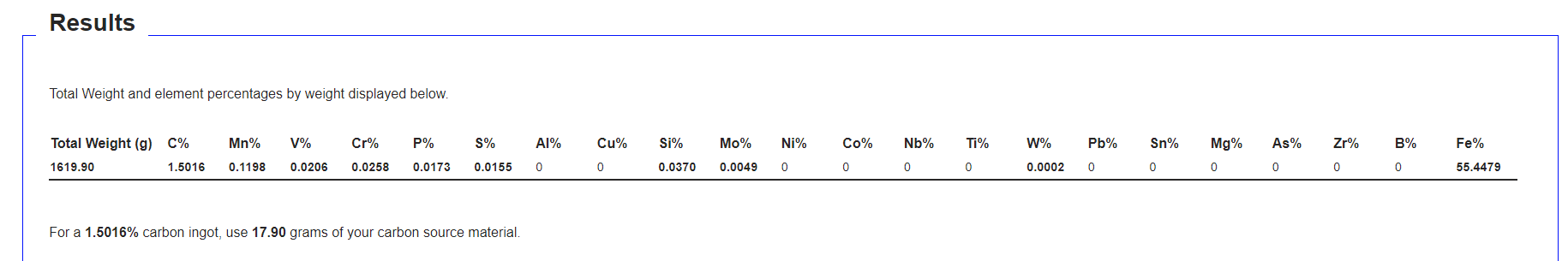

Calculated chemical composition for the above recipe

@ajfmetalworks What you listed here is pretty much what I started with in my own melts, minus the electrolytic iron flake because I didnt learn about that until later.

I have used O1 a bit but prefer W2 over it just because it is much less alloyed. I have found that most ferrro alloys that we would use for making wootz are pretty difficult to come across.

Recently I have been using CPM S90V as my vanadium source and CPM 154 for addition of chromium. I am sticking to the CPM steels because of how they are made. The thought is that making steel with particle metallurgy, the distribution of alloying elements should be much more even. So when you calculate a certain piece having a certain amount of vanadium in it, it should hopefully be at least somewhat close to that.

I will also mention that using graphite pellets can be easier to use that graphite powder because it wont blow out of the crucible. If you do use the graphite powder, I would suggest that you mix it with your powdered steel. If you are using different types of powdered steel, mix them all together before pouring it into the crucible. This it will help the graphite be absorbed better. If using the pellets, I would put them closer to the bottom but not at the bottom. They like to float in the glass slag lol....

Here is a basic recipe that will give you a decent pattern. It is not historical wootz but not entirely far off either.

Calculated chemical composition for the above recipe