Quote from Raggedyman on October 2, 2024, 12:34 amWith my first blade having rather short, irregular, and generally inadequate dendritic formation and spacing I hit the books again.

This will be a series of posts (each in a different area of the forum, where it fits) documenting failure, the reason for it, subsequent success, and how the problem was fixed.

Below we see my first successful ingot, with very narrow banding. See the second photo of a newer one with much wider spacing and more prominent banding, visible without zooming the camera in.

Note also that the first ingot came from a much larger crucible, so was a flat-ish disc shape. The second is notably narrower (smaller from the camera perspective), yet the spacing is still easily visible

With my first blade having rather short, irregular, and generally inadequate dendritic formation and spacing I hit the books again.

This will be a series of posts (each in a different area of the forum, where it fits) documenting failure, the reason for it, subsequent success, and how the problem was fixed.

Below we see my first successful ingot, with very narrow banding. See the second photo of a newer one with much wider spacing and more prominent banding, visible without zooming the camera in.

Note also that the first ingot came from a much larger crucible, so was a flat-ish disc shape. The second is notably narrower (smaller from the camera perspective), yet the spacing is still easily visible

Uploaded files:Quote from Raggedyman on October 2, 2024, 1:20 amSo, onto what changed:

Firstly, my cooling rate was decently slow, but not at the right time. I'm sure pretty much everyone who reads this has read the relevant documents, but I attach them nonetheless.

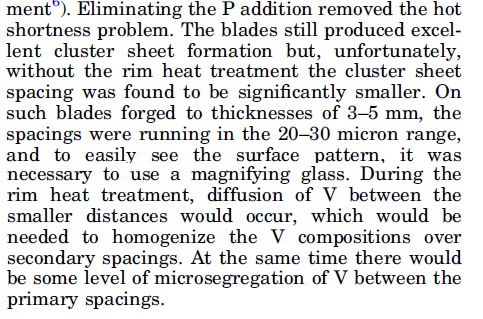

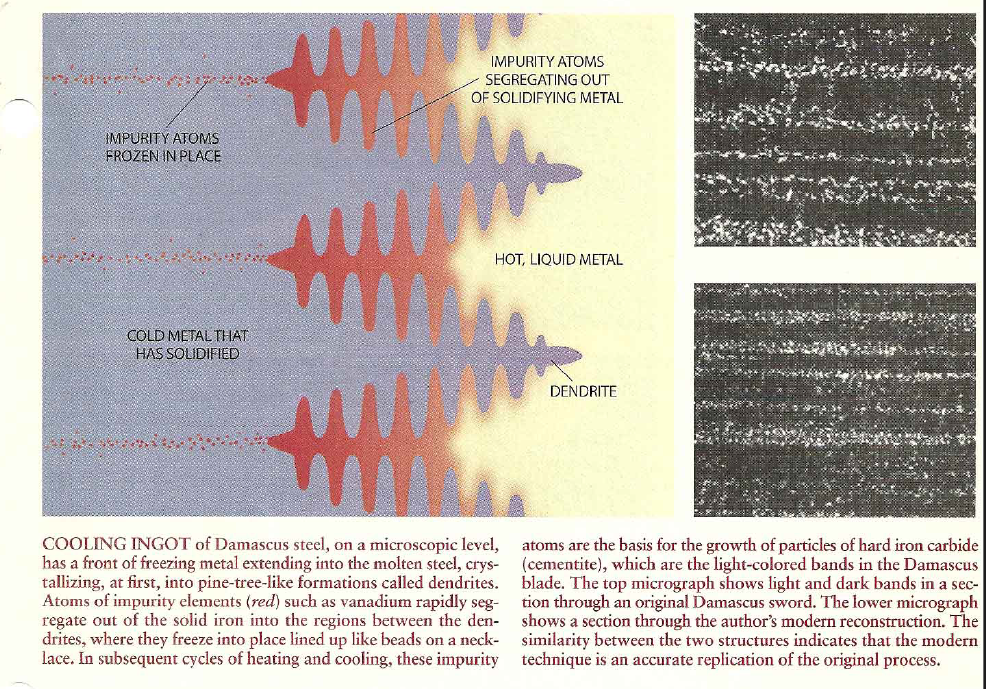

As can be seen from the excerpt of the original piece written by Verhoeven (The Mystery of Damascus Blades), The moment of solidification is when you have to cool it rather slowly:

Having run my furnace at around 1650 Celcius (around 3000 Fahrenheit), I started cooling slowly as recommended, and after cooling slowly for an hour (dropping about 200 degrees in said hour) I figured it was enough and stopped.

Here-in lies the problem, The metal was likely not yet solidified.

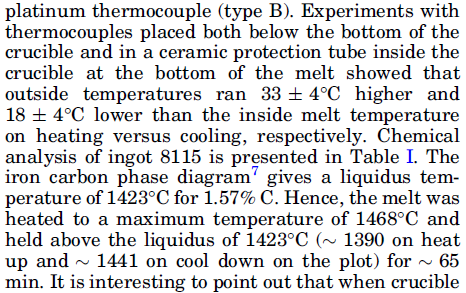

Quoted from the Verhoevens subsequent update (Damscus steel revisited), we see that the temperature inside the crucible is a good bit higher during cool-down than the measured temperature in the furnace (Duh. Don't know how I didn't think of that part myself).

With the 1.59% C steel (close enough to my amount to be comparable), the steel is still liquid at 1423 Degrees C. In short: I stopped my slow cool at around 1450C, before my steel solidified. For the next melt I started slow-cooling at 1440C (with the idea that inside the crucible it would likely still be at around 1470), and cooled slowly for about 40 minutes to 1310.

Note also that in the update that we see in their graphs of holding times that they turned the gas off and went "ok, all done" shortly after dropping below solidification. (ingot 8115, which was successful), further leading me to believe that this is the critical time.

All in all my dendritic spacing seems much better, and I'll post a picture of the blade oince it's been forged and etched.

As a last note, I have read a few smiths say that they don't really bother with the "roasting" of the ingot (Verhoeven calls it the "Rim heat treatment") because they find that their ingot doesn't just come apart as Verhoeven and Pendrays did (see below). Verhoeven says that the original reason was the Phosphorous content, and without too much Phosphorous it was no longer necessary, but that it does help a lot with the pattern. I will increase my roast time (it was only 2.5 hours with the first ingot) and post results.

So, onto what changed:

Firstly, my cooling rate was decently slow, but not at the right time. I'm sure pretty much everyone who reads this has read the relevant documents, but I attach them nonetheless.

As can be seen from the excerpt of the original piece written by Verhoeven (The Mystery of Damascus Blades), The moment of solidification is when you have to cool it rather slowly:

Having run my furnace at around 1650 Celcius (around 3000 Fahrenheit), I started cooling slowly as recommended, and after cooling slowly for an hour (dropping about 200 degrees in said hour) I figured it was enough and stopped.

Here-in lies the problem, The metal was likely not yet solidified.

Quoted from the Verhoevens subsequent update (Damscus steel revisited), we see that the temperature inside the crucible is a good bit higher during cool-down than the measured temperature in the furnace (Duh. Don't know how I didn't think of that part myself).

With the 1.59% C steel (close enough to my amount to be comparable), the steel is still liquid at 1423 Degrees C. In short: I stopped my slow cool at around 1450C, before my steel solidified. For the next melt I started slow-cooling at 1440C (with the idea that inside the crucible it would likely still be at around 1470), and cooled slowly for about 40 minutes to 1310.

Note also that in the update that we see in their graphs of holding times that they turned the gas off and went "ok, all done" shortly after dropping below solidification. (ingot 8115, which was successful), further leading me to believe that this is the critical time.

All in all my dendritic spacing seems much better, and I'll post a picture of the blade oince it's been forged and etched.

As a last note, I have read a few smiths say that they don't really bother with the "roasting" of the ingot (Verhoeven calls it the "Rim heat treatment") because they find that their ingot doesn't just come apart as Verhoeven and Pendrays did (see below). Verhoeven says that the original reason was the Phosphorous content, and without too much Phosphorous it was no longer necessary, but that it does help a lot with the pattern. I will increase my roast time (it was only 2.5 hours with the first ingot) and post results.