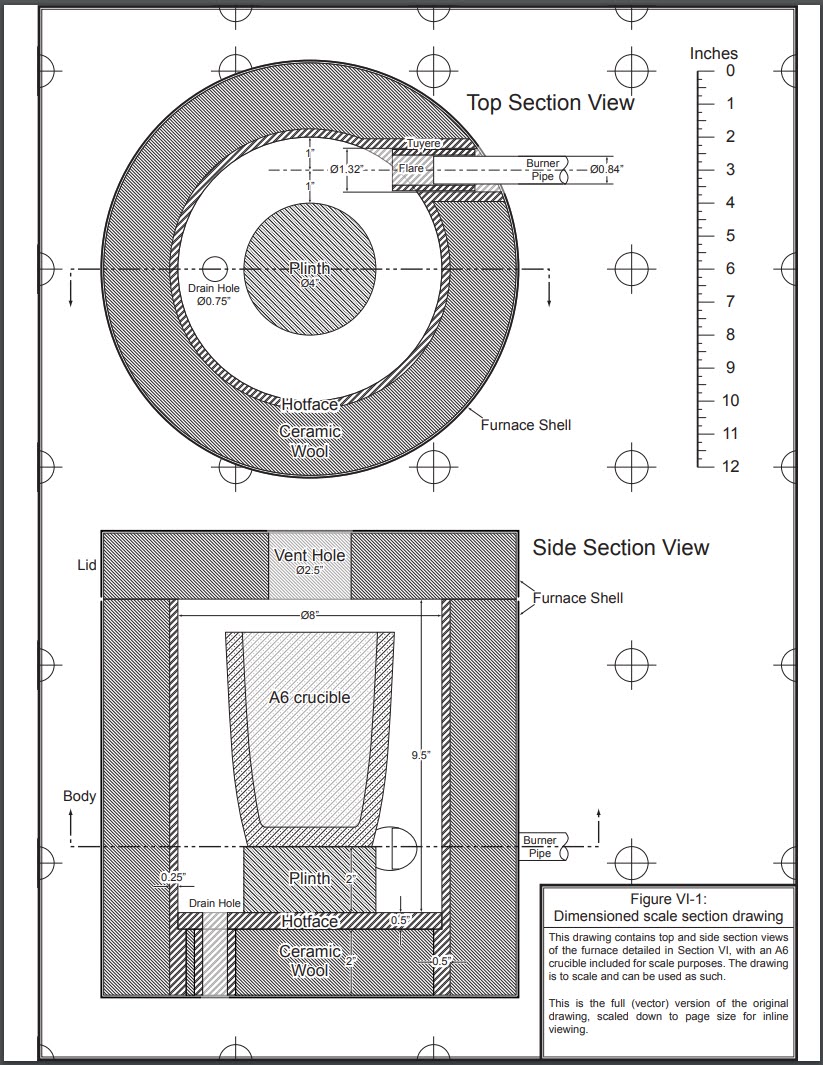

Quote from Jacob Christian on August 7, 2023, 6:54 amNew low mass furnace build with kastolite 30. Parts list below.

2 in on the floor which was then covered with .5 in kastolite 30 - Amazon.com: Ceramic Fiber Insulation Board (2300 F) (1" X 12" X 24") Fireproof Insulation Board for Wood Stoves, Pizza Ovens, Forges, Kilns, Furnaces - Pack of 1 : Arts, Crafts & Sewing

These pieces made up the wall of the furnace and were then covered with min .5 in kastolite 30 - Amazon.com: BXI Ceramic Fiber Thermal Insulation Board(2732F) - 12'' X 8'' X 0.8'', Pack of 1 - Inorganic - Flame Retardant, Heat Resistant, High Temperature Insulation

AMERIMAX HOME PRODUCTS 70412 12-Inch x10-Feet Galvanized Flashing - Roof Flashing - Amazon.com

MR VOLCANO Refractory Satanite 10 Pounds for Ceramic Blanket Lining 3200 Degree Mortar

Kastolite 30 Plus Refractory Mix 55# Bag | eBay

Quikrete QUIK-TUBE 8 in. x 48 in. Building Form Tube 692201 - The Home Depot

New low mass furnace build with kastolite 30. Parts list below.

2 in on the floor which was then covered with .5 in kastolite 30 - Amazon.com: Ceramic Fiber Insulation Board (2300 F) (1" X 12" X 24") Fireproof Insulation Board for Wood Stoves, Pizza Ovens, Forges, Kilns, Furnaces - Pack of 1 : Arts, Crafts & Sewing

These pieces made up the wall of the furnace and were then covered with min .5 in kastolite 30 - Amazon.com: BXI Ceramic Fiber Thermal Insulation Board(2732F) - 12'' X 8'' X 0.8'', Pack of 1 - Inorganic - Flame Retardant, Heat Resistant, High Temperature Insulation

AMERIMAX HOME PRODUCTS 70412 12-Inch x10-Feet Galvanized Flashing - Roof Flashing - Amazon.com

MR VOLCANO Refractory Satanite 10 Pounds for Ceramic Blanket Lining 3200 Degree Mortar

Kastolite 30 Plus Refractory Mix 55# Bag | eBay

Quikrete QUIK-TUBE 8 in. x 48 in. Building Form Tube 692201 - The Home Depot

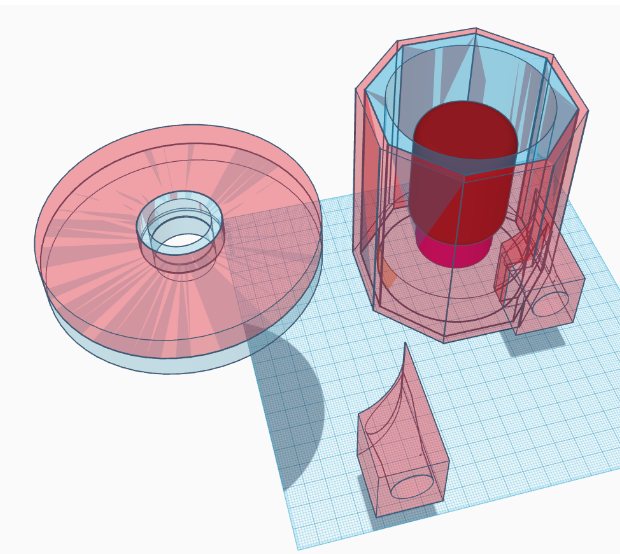

Uploaded files:Quote from Jacob Christian on August 7, 2023, 6:55 amThe burner block was mocked up in CAD software and then 3D printed to make a form.

The burner block was mocked up in CAD software and then 3D printed to make a form.

Uploaded files:Quote from Jacob Christian on August 7, 2023, 6:58 amThe outside was wrapped in ceramic blanket and then covered with galvanized steel flashing. The wool was then pushed below the top of the furnace and sealed with more kastolite 30.

The outside was wrapped in ceramic blanket and then covered with galvanized steel flashing. The wool was then pushed below the top of the furnace and sealed with more kastolite 30.

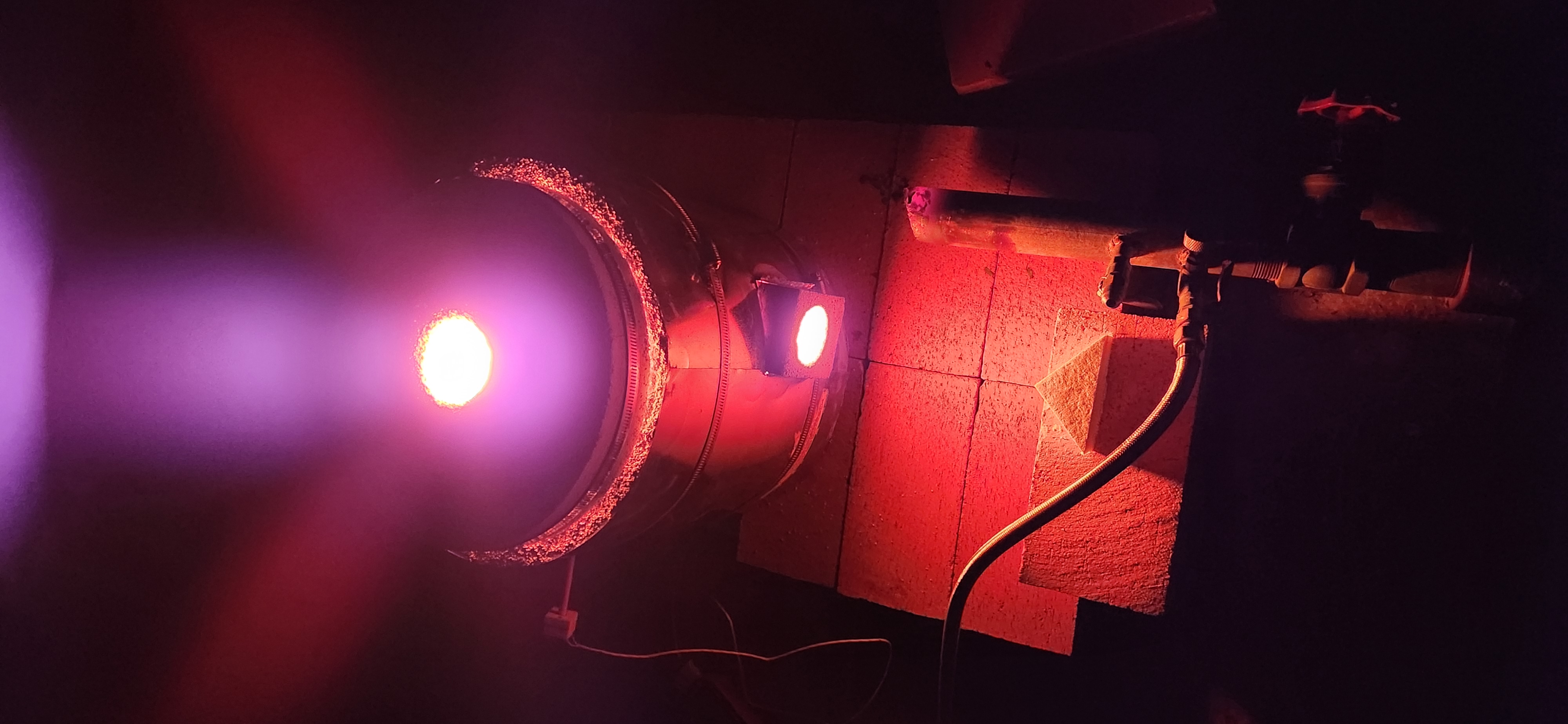

Uploaded files:Quote from Jacob Christian on August 7, 2023, 7:01 amWhen the kastolite was first poured, it was wrapped in a trash bag for a day and then taken out and left to sit for a week. The furnace was slowly taken to 1550C over the course of a day with increasing temps and intensity every hour.

In the final 1550C burn picture my camera picked up IR radiation coming from the furnace. Pretty cool picture!!

When the kastolite was first poured, it was wrapped in a trash bag for a day and then taken out and left to sit for a week. The furnace was slowly taken to 1550C over the course of a day with increasing temps and intensity every hour.

In the final 1550C burn picture my camera picked up IR radiation coming from the furnace. Pretty cool picture!!

Uploaded files:Quote from Jacob Christian on August 7, 2023, 7:54 amLink to a PDF with tons of information about metal casting, furnace builds, and mold making.

https://drive.google.com/file/d/10mC9FsBKQVgQl_XXLIxIXXQ3XAni-I-Y/view?usp=sharing

Link to a PDF with tons of information about metal casting, furnace builds, and mold making.

https://drive.google.com/file/d/10mC9FsBKQVgQl_XXLIxIXXQ3XAni-I-Y/view?usp=sharing

Uploaded files:

Quote from Jerry Martin on May 30, 2024, 5:11 pmWow, Ben's book is making the rounds. I have a copy of this. I think he started writing this at the end of Backyard metalcasting. It switched to Alloy Avenue and then died off when the founder kind of disappeared. Never heard what happened to him, his site is still open. Melting metal in a home foundry, backyard metalcasting, metal casting but he hasn't posted anything since 2018.

Well, My name is Jerry and I've been around metal and hot stuff most of my life. I've retired from a Steel Mill where I was a Chem Lab Tech. Basically I tested all the steel we produced during my shift. Ran the chemistry on a spectrometer and did the tensile testing of the finished product. I learned a lot about the low alloy steels we produced. Mostly less than .25 Carbon and .95 Manganese. The highest Carbon we produced was .70 C and .80 Mn. This is the alloy used for train rails but we rolled it into signposts for along the road. I started melting metals in 2007 and melt mostly Bronze and Aluminum. I have cast some Iron and hope to do some this summer. I was in on a couple Iron smelts, they were fun, but I didn't get to work with any of the metal. I have almost a hundred pounds of Iron Ore and hope to smelt some someday. I've also been a welder and hydraulic tech and done some Blacksmithing for about 10 years. I have only made 1 knife but, hope to make a wrought iron and file insert tomahawk this year.

Wow, Ben's book is making the rounds. I have a copy of this. I think he started writing this at the end of Backyard metalcasting. It switched to Alloy Avenue and then died off when the founder kind of disappeared. Never heard what happened to him, his site is still open. Melting metal in a home foundry, backyard metalcasting, metal casting but he hasn't posted anything since 2018.

Well, My name is Jerry and I've been around metal and hot stuff most of my life. I've retired from a Steel Mill where I was a Chem Lab Tech. Basically I tested all the steel we produced during my shift. Ran the chemistry on a spectrometer and did the tensile testing of the finished product. I learned a lot about the low alloy steels we produced. Mostly less than .25 Carbon and .95 Manganese. The highest Carbon we produced was .70 C and .80 Mn. This is the alloy used for train rails but we rolled it into signposts for along the road. I started melting metals in 2007 and melt mostly Bronze and Aluminum. I have cast some Iron and hope to do some this summer. I was in on a couple Iron smelts, they were fun, but I didn't get to work with any of the metal. I have almost a hundred pounds of Iron Ore and hope to smelt some someday. I've also been a welder and hydraulic tech and done some Blacksmithing for about 10 years. I have only made 1 knife but, hope to make a wrought iron and file insert tomahawk this year.