Quote from Jacob Christian on June 28, 2022, 4:25 pmHere is one of my upcoming recipes. This one is slightly different form the last in that it has more chromium added.

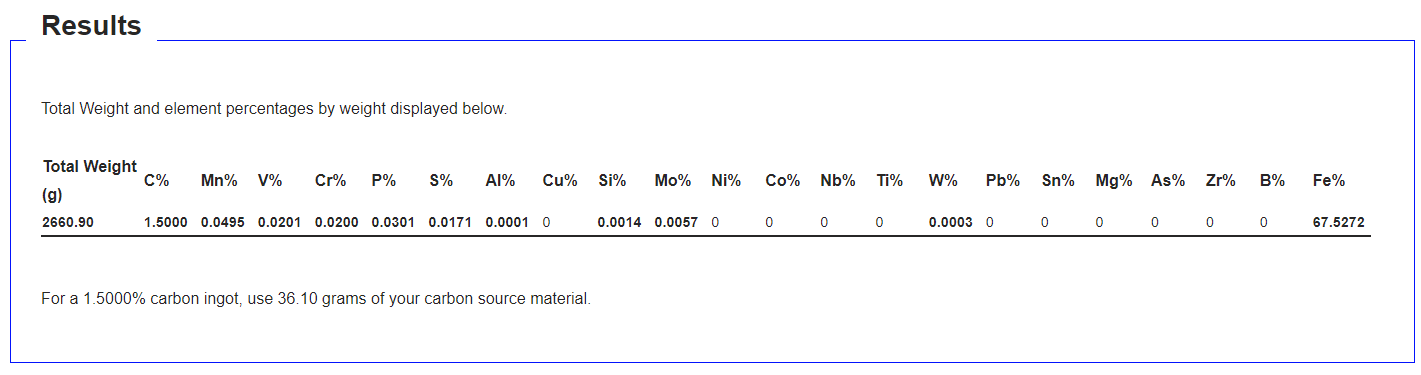

Here is one of my upcoming recipes. This one is slightly different form the last in that it has more chromium added.

Quote from Raggedyman on December 26, 2022, 1:38 amAny results you can post on how it turned out?

Also how did the graphite work as carburising medium instead of something like coke?

I've been considering my first melt, but still trying to figure out if I can reach a high enough heat - while pack carburising I have accidentally melted a piece in the past, so hoping so, but I'll have to see.

I've heard of people using graphite crucible for the melt l, and have wondered how.kuch would get absorbed, whether it would turn your steel to pig iron.

Any results you can post on how it turned out?

Also how did the graphite work as carburising medium instead of something like coke?

I've been considering my first melt, but still trying to figure out if I can reach a high enough heat - while pack carburising I have accidentally melted a piece in the past, so hoping so, but I'll have to see.

I've heard of people using graphite crucible for the melt l, and have wondered how.kuch would get absorbed, whether it would turn your steel to pig iron.

Quote from Jacob Christian on January 1, 2023, 5:56 pmThe graphite works well you just have to load it into the crucible in a specific manner.

Mine I completely mix in with 1095 powder and then layer the powder and electrolytic iron in alternating layers. Then the last layer is electrolytic iron and this will help to keep the powder from blowing out. I use an open crucible.

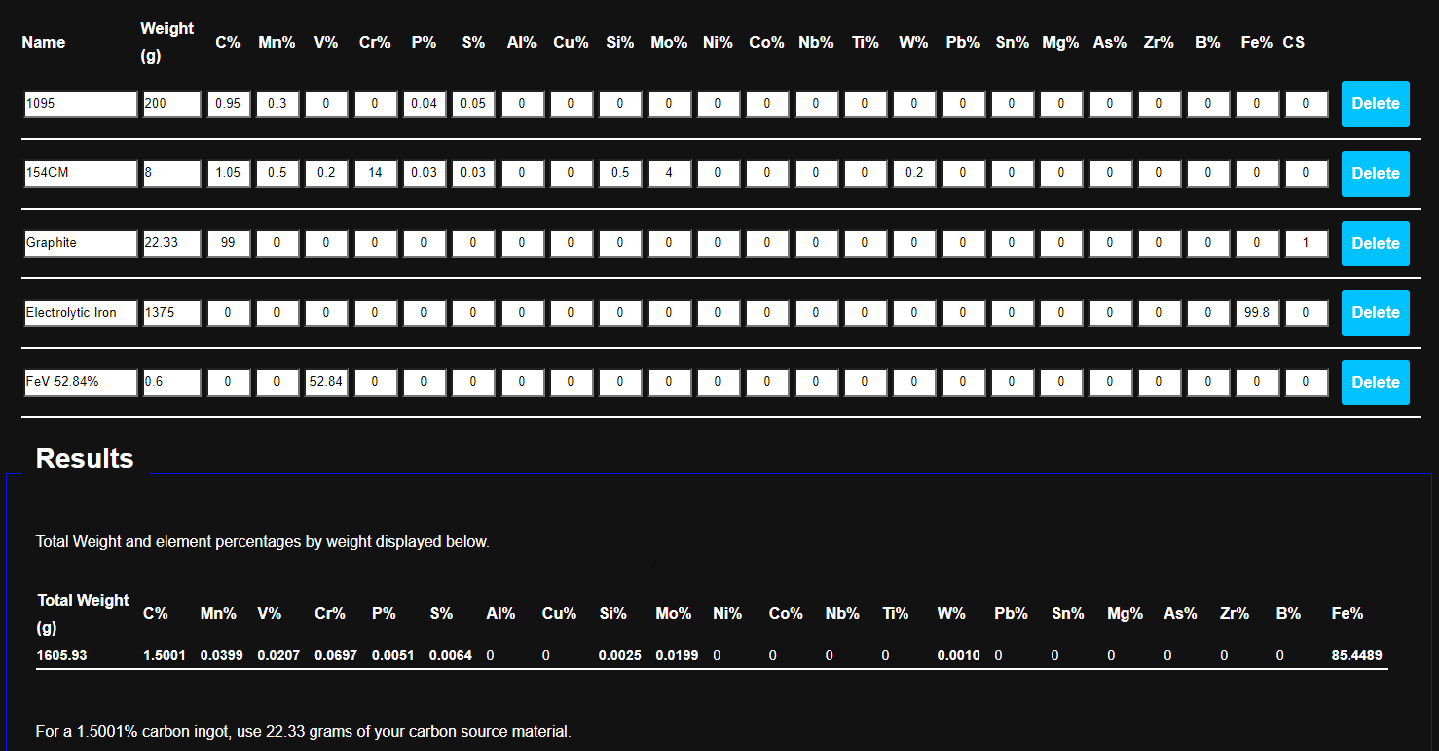

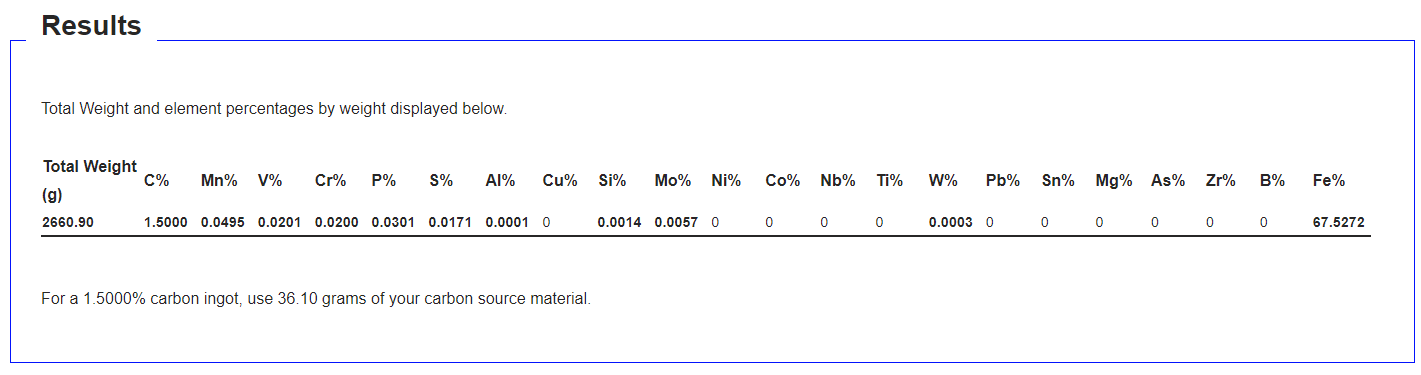

This specific melt turned out alright but I would say higher P and lower Cr is more of what I like. The melt giving the best results is something like this:

The graphite works well you just have to load it into the crucible in a specific manner.

Mine I completely mix in with 1095 powder and then layer the powder and electrolytic iron in alternating layers. Then the last layer is electrolytic iron and this will help to keep the powder from blowing out. I use an open crucible.

This specific melt turned out alright but I would say higher P and lower Cr is more of what I like. The melt giving the best results is something like this:

Quote from Jacob Christian on January 1, 2023, 5:58 pmAlso the higher Mn makes it much easier to quench. I like a fully quench blade more than the ghostly hamon.

Also the higher Mn makes it much easier to quench. I like a fully quench blade more than the ghostly hamon.

Quote from Raggedyman on April 5, 2023, 12:54 amDid it seem like the manganese made a difference when you quenched?

It's a remarkably small amount. Then again I don't know how much is required to see a difference

Did it seem like the manganese made a difference when you quenched?

It's a remarkably small amount. Then again I don't know how much is required to see a difference

Quote from Jacob Christian on April 5, 2023, 10:07 amNo it did not make too much of a difference. Talking with some other makers, I was told that adding between .03 -.05% Copper will help with hardening. So I am going to give that a shot!

No it did not make too much of a difference. Talking with some other makers, I was told that adding between .03 -.05% Copper will help with hardening. So I am going to give that a shot!