Quote from Jacob Christian on February 27, 2023, 10:08 am-INGOT JEC*028-

Starting a new wootz knife styled after the Loveless Utility Hunter.

Melted a 3.2Kg ingot

After melting the ingot, it went into a kiln with some charcoal at 1080 C for 5 hours to spheroidize. The charcoal is added in the kiln to create a reducing atmosphere.

After that it was worked on a 25 ton hydraulic press with the following parameters

1080 - 960 C -> 15 Cycles This gets the bar to about 16 mm thick

Once main reduction of the bar has taken place the heat is dropped down to start coarsening the cementite.

950 - 800 C -> 20 Cycles

Secondary forging starts and all imperfections/cracks are ground out of the steel. Check for pattern and depth of decarb.

The knife is ground out of the 1/4 in bar and all decarb removed. It was then heat treated but developed a slight warp. I tried to straighten it in a vise and end up dropping something of the handle and over tightened it and the tip snapped off. Plus side is that now I get to inspect the internal microstructure and everything looks good.

Sooooo then I had to forge out another blade.... Things are looking great while forging at about 800C

Further forging and we have a look at the pattern.

More to come on this one...

-INGOT JEC*028-

Starting a new wootz knife styled after the Loveless Utility Hunter.

Melted a 3.2Kg ingot

After melting the ingot, it went into a kiln with some charcoal at 1080 C for 5 hours to spheroidize. The charcoal is added in the kiln to create a reducing atmosphere.

After that it was worked on a 25 ton hydraulic press with the following parameters

1080 - 960 C -> 15 Cycles This gets the bar to about 16 mm thick

Once main reduction of the bar has taken place the heat is dropped down to start coarsening the cementite.

950 - 800 C -> 20 Cycles

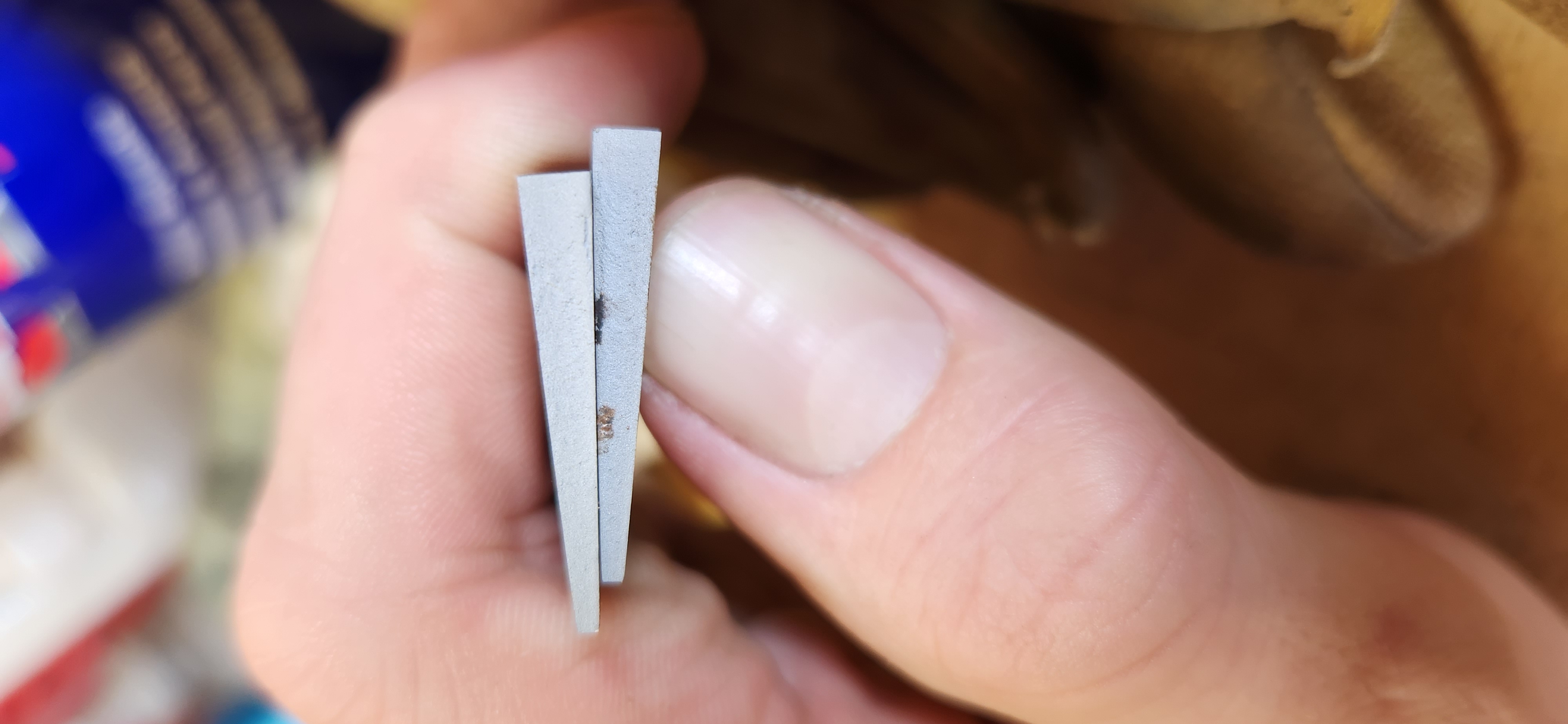

Secondary forging starts and all imperfections/cracks are ground out of the steel. Check for pattern and depth of decarb.

The knife is ground out of the 1/4 in bar and all decarb removed. It was then heat treated but developed a slight warp. I tried to straighten it in a vise and end up dropping something of the handle and over tightened it and the tip snapped off. Plus side is that now I get to inspect the internal microstructure and everything looks good.

Sooooo then I had to forge out another blade.... Things are looking great while forging at about 800C

Further forging and we have a look at the pattern.

More to come on this one...

Uploaded files:

Quote from Jacob Christian on February 27, 2023, 10:36 amProfiled and surface ground Loveless Utility Hunter

Tempered Knife - 210C for 2 hours x 2

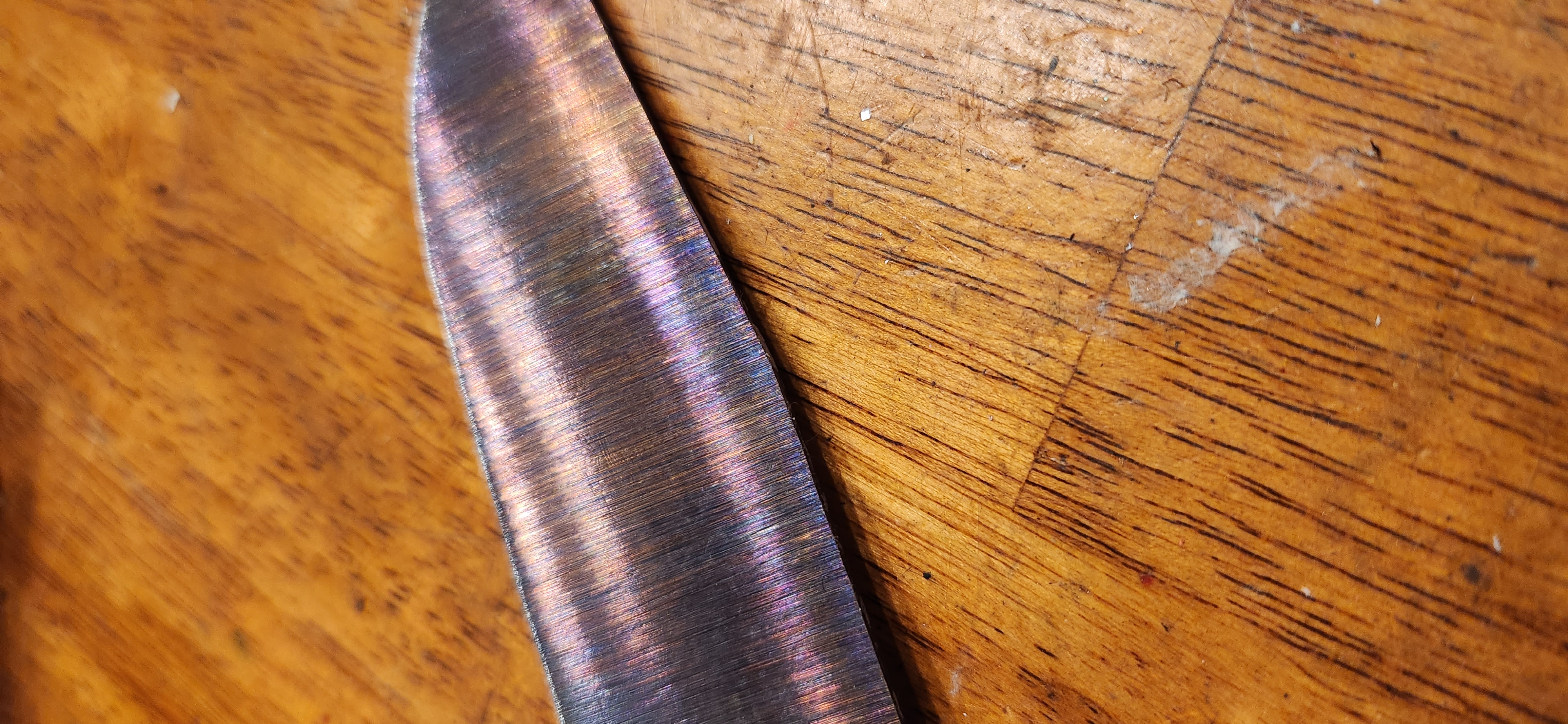

I take the temper up a little higher for wootz because it seems like it is too hard at 200C slight straw color in places but mostly Red-Brown to Purple.

Note how the pattern can be seen at 36 grit through the temper colors.

The video on here is off the knife being dropped on my anvil. It has quite a wonderful ring to it. Though this is both the knife and the anvil ringing.

Picture of the pattern after heat treat.

Profiled and surface ground Loveless Utility Hunter

Tempered Knife - 210C for 2 hours x 2

I take the temper up a little higher for wootz because it seems like it is too hard at 200C slight straw color in places but mostly Red-Brown to Purple.

Note how the pattern can be seen at 36 grit through the temper colors.

The video on here is off the knife being dropped on my anvil. It has quite a wonderful ring to it. Though this is both the knife and the anvil ringing.

Picture of the pattern after heat treat.

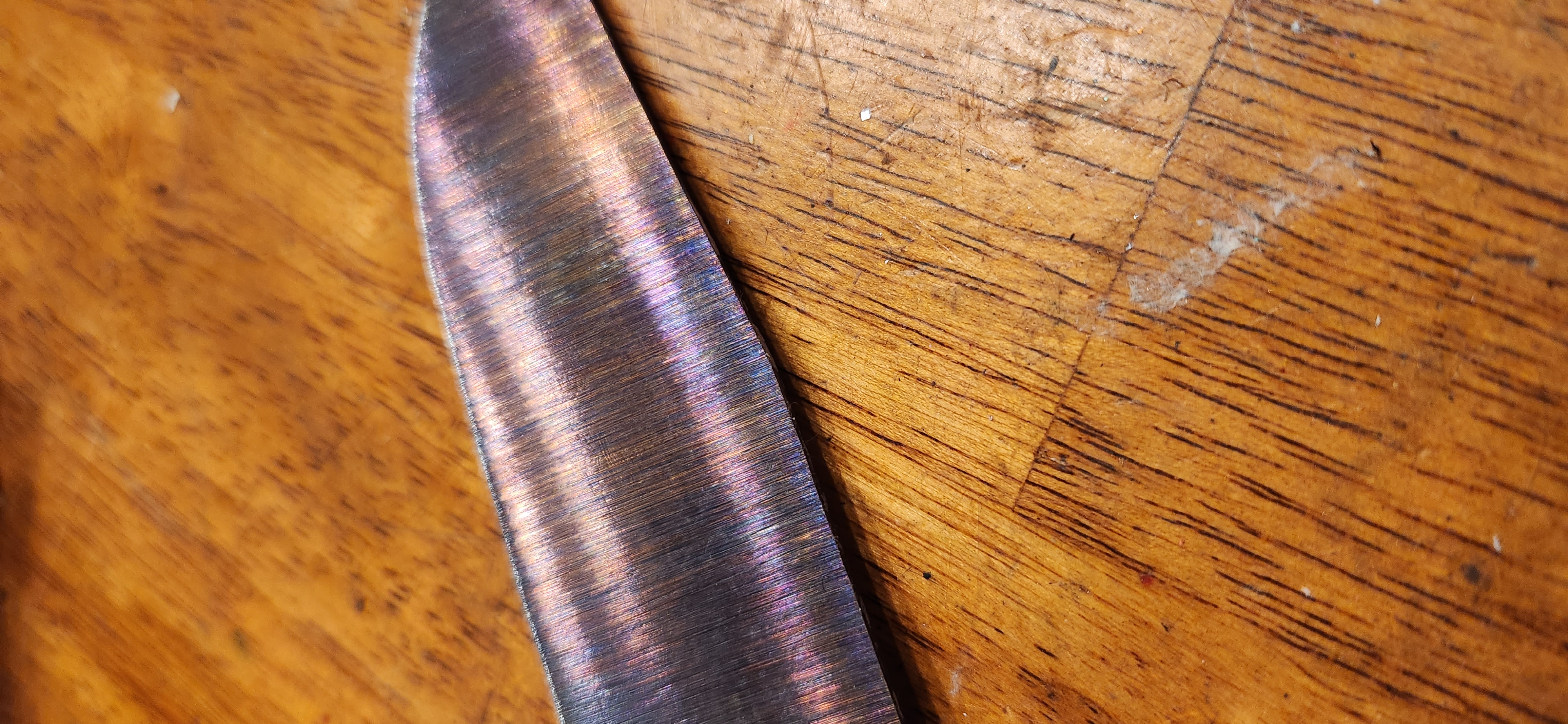

Quote from Jacob Christian on March 1, 2023, 7:13 amQuick little update on the post heat treat pattern. Things came out exactly as I had expected and the pattern is wonderfully watered!

Quick little update on the post heat treat pattern. Things came out exactly as I had expected and the pattern is wonderfully watered!